Clearing The Air

Since launching in 2017, Syzygy Plasmonics has raised $106 million in capital, largely from some of the biggest players in the global energy and chemical industries. Their collective goal: Remove a gigaton of carbon from entering the atmosphere by 2040.

When Suman Khatiwada and Trevor Best decided to call their cleantech startup Syzygy Plasmonics, they knew the seemingly made-up name would meet resistance from the folks in marketing.

“But we didn’t care,” Khatiwada says from the company’s headquarters, located in a nondescript office park just a few miles south of Rice University.

For one thing, there was nothing made-up about it. Though plasmonics might not sound like a real word, it in fact refers to a core element of the company’s technology. Similarly, the term syzygy describes an alignment of three or more celestial bodies, though in this case its three y’s represent the alignment of energy, technology and sustainability — the animating ideas behind the startup, which uses science and engineering to remove carbon emissions from industrial chemical processing.

And in a crowded cleantech market, having an unusual name turned out to be helpful.

“Once people got it, they seemed to gravitate toward it,” says Khatiwada, who earned a Ph.D. in materials science and nanoengineering at Rice in 2013 and is now Syzygy’s chief technology officer. (Best is CEO.)

That may be an understatement. Since launching in 2017, Syzygy has raised $106 million in capital. Much of that comes from strategic partners that represent some of the biggest players in the global energy and chemical industries, including BP Ventures, Chevron Ventures and LOTTE Chemical.

Their interest, explains VP of finance and corporate development Murtuza Marfani ’19, stems from Syzygy’s attempt to decarbonize the “trillion-dollar value chain” of the chemical industry. The first link in that chain involves turning feedstocks such as petroleum and natural gas into base chemicals like hydrogen and ammonia, which can be used to manufacture everything from fuels and fertilizers to plastics and cosmetics.

As important as that value chain is — and much of modern life depends on it — it is also highly carbon intensive. Industrial chemical processing relies on catalysts to increase the rate of chemical reactions. But conventional catalysts require huge amounts of heat and pressure to do their work (temperatures inside a chemical reactor can exceed 1500° F). And the easiest and cheapest way to generate that heat and pressure is to burn fossil fuels.

As a result, chemical production currently accounts for 1 gigaton, or roughly 3.6%, of global greenhouse gas emissions. Reducing those numbers would represent a significant step toward combating climate change and a major boon to energy companies and chemical manufacturers that are navigating the transition to a low-carbon economy.

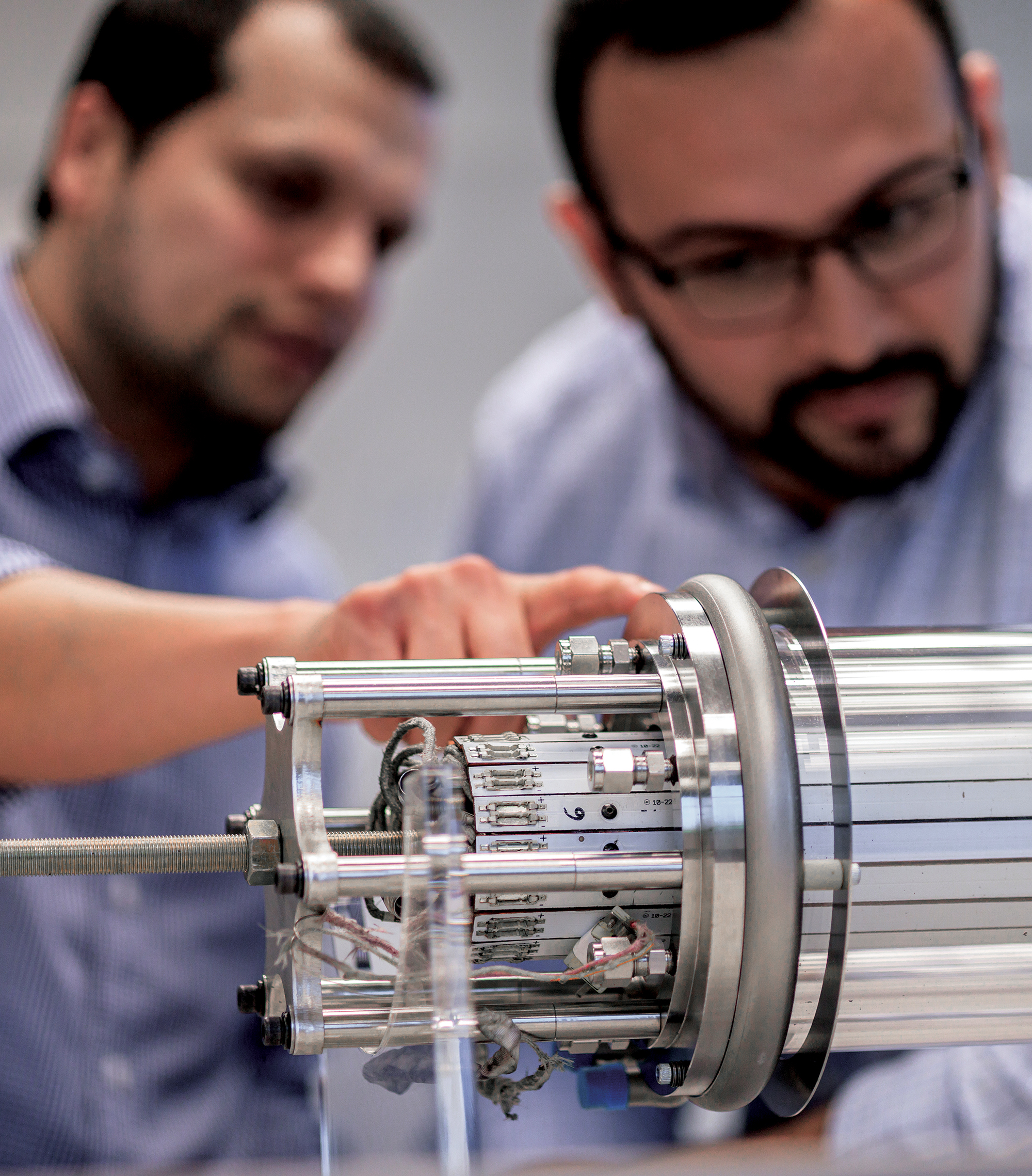

Syzygy has found a way to slash emissions from this hard-to-abate sector. Using novel light-driven catalysts developed at Rice and an electrified, light-powered reactor of its own devising, the startup can process chemicals such as hydrogen and ammonia without having to cook them at high heat and pressure. If the reactor draws electricity from renewable sources like wind or solar, fossil fuels can be cut out of the picture entirely.

Just as importantly, when operating at commercial scale, Syzygy’s clean approach to chemical processing promises to compete on price with conventional methods — a key factor when courting venture capitalists and industry partners whose eyes are focused on the bottom line.

Syzygy will enter field trials of its system in the U.S. and Asia this year and intends to prevent 1 gigaton of carbon dioxide from entering the atmosphere by 2040. But the company’s leadership is already thinking even bigger.

“For us, the ultimate ambition would be to completely eliminate emissions from any refinery complex,” says Marfani. “If we are able to get there, the world has a fighting chance against climate change.”

Syzygy was born when Khatiwada and Best both worked for Baker Hughes, one of the world’s largest oil field services companies — Best as a manager, Khatiwada as a research scientist. But Khatiwada, for his part, was no stranger to cleantech.

While earning his doctorate in materials science and nanoengineering, Khatiwada took classes on the side at Rice Business and participated in business plan competitions run by the Rice Alliance for Technology and Entrepreneurship. He now mentors cleantech founders at the Rice Alliance Clean Energy Accelerator.

“I wanted to see what MBAs actually learned,” he says.

He caught on fast: In 2013, with support from the alliance’s OwlSpark Startup Accelerator, Khatiwada and some friends founded Big Delta Systems — now called EnPower — a startup devoted to commercializing the cutting-edge lithium-ion battery technology they had developed at Rice.

At Baker Hughes, Khatiwada and Best discovered a shared interest in new, sustainable business models and eventually decided to find one they could develop on their own.

They began by scouting the latest technologies to emerge from top research universities, applying a framework they called TMI, for “technology, market, impact.” Their goal was to identify something that was based on solid fundamental science, had global market potential and could contribute to the greater good.

In 2016, the two found what they were looking for. That year, Rice researchers Peter Nordlander and Naomi Halas unveiled a new breed of photocatalyst that could drive chemical reactions by harvesting energy from light. By using so-called plasmonic nanoparticles to energize other nanoparticles made from traditional chemical catalysts, Nordlander and Halas discovered they could make and break chemical bonds without high pressures and temperatures. And because their novel photocatalysts could be “tuned” to many different chemical reactions, they had any number of potential applications.

“It checked all the boxes,” says Khatiwada, who set up a meeting with Nordlander to pitch the idea of pairing the researchers’ invention with a fully electrified, light-driven chemical reactor.

Nordlander was sold, as was Halas. The two joined Khatiwada and Best as co-founders, and Syzygy Plasmonics was born.

According to Marfani, who worked as a derivatives trader and investment banker before joining Syzygy in 2021 and who holds a B.A. in mathematical economic analysis from Rice, the startup will generate revenues by selling its reactors, licensing its technology, and providing service and maintenance to its customers, who will be able to use the platform as they like.

The startup’s strategic partners have already been quite clear about the applications they are most interested in, however. And Syzygy has been quick to respond.

Initially, says Khatiwada, the company’s goal was to extract hydrogen from methane. In addition to being the most abundant element in the universe, hydrogen produces zero emissions when burned or used in fuel cells and is regarded as one of the building blocks of a low-carbon future. Unfortunately, the conventional method of separating hydrogen from methane generates large quantities of carbon dioxide, some of which comes from burning fossil fuels and some of which comes from the process itself. Using its electrified reactor, Syzygy reduced those emissions by 43%.

Over time, however, the startup’s industry backers let Khatiwada and his colleagues know that they were more interested in making hydrogen by splitting, or “cracking,” ammonia. Although it is chock-full of hydrogen, ammonia can be stored and transported far more easily and cheaply, making it a convenient hydrogen carrier. The chemical reaction that separates hydrogen from ammonia does not generate any CO2. And depending on how it is treated, ammonia itself can serve as a low-emissions or zero-emissions fuel.

A grant from ARPA-E (Advanced Research Projects Agency–Energy) allowed Syzygy to develop an ammonia-cracking process, and last fall the company announced that it was partnering with international chemical heavyweights LOTTE and Sumitomo to deploy and test an ammonia-cracking reactor powered by renewable energy in South Korea later this year. Khatiwada expects this upcoming field trial to produce perhaps 250 kilograms of hydrogen per day, whereas a large conventional plant might turn out 50 to 60 tons of the stuff. But if things go well, he anticipates ramping up to commercial-scale production within two to three years.

Industry investors also signaled interest in using Syzygy’s multipurpose platform to turn CO2 into something useful. With support from the National Science Foundation, the startup developed a method of transforming CO2 into syngas, a key ingredient in synthetic fuels and other products. This past January, the company announced that it would launch a field trial of the process in North Carolina aimed at making low-carbon fuels. If it succeeds, Syzygy could help decarbonize the transportation sector — which generates nearly a third of all U.S. greenhouse gas emissions — by replacing conventional jet fuel, diesel and gasoline with sustainable, CO2-derived fuels.

Syzygy is also pursuing efforts to crack hydrogen sulfide — a smelly, toxic chemical produced by petroleum refineries and sewage treatment plants — and synthesize ammonia. Making ammonia in Syzygy’s electrified reactors would allow customers to manufacture the chemical in places like North Africa and Australia, where wind and solar power are cheap and plentiful, and then ship it to markets in Europe and Asia, where it could be converted into hydrogen and other useful substances.

Taken together, these various initiatives would allow industry to reduce emissions without paying a green premium — and allow Syzygy and its allies to make money while mitigating climate change.

“That,” says Khatiwada, “is true disruption.”